Contents

Platinum utilization

The six Platinum Group Metals (i.e., platinum, palladium, rhodium, iridium, ruthenium and osmium) are chemically very similar and are used for many applications.

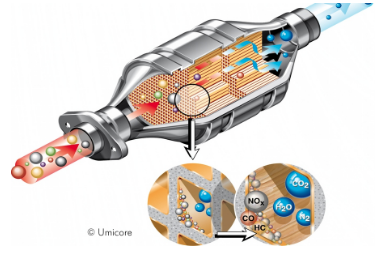

Autocatalyst

An autocatalyst is a cylinder or elliptical cross section made from ceramic or metal formed into a fine honeycomb and coated with a solution of chemicals and a combination of platinum, rhodium and/or palladium. It is mounted inside a stainless steel canister (the whole assembly is called a catalytic converter) and installed in a vehicle's exhaust line where it converts pollutants from the combustion of fuel into harmless gases. Without PGMs, the desired conversion reactions in the catalytic converter would not take place, resulting in the vehicle not meeting the emissions regulations. Other materials have been tried, but have not met the long term activity and durability requirements of modern-day emission control systems.The activity of the PGMs enables the reactions to occur at low temperature conditions that exist during cold starting of a vehicle, when emissions are at their highest. Durability is important since catalytic converters need to perform over the life of the vehicle. It also means that when an automobile is scrapped the precious metal contained in the catalytic converter is available for recycling, creating a valuable supplementary source to mining for the production of new autocatalysts. Platinum Group Metals are therefore an important features for the development of automobile industry.