Project Description

Overview

When conducting a project there are many aspects to consider. LiU iGEM has been working within different areas such as human practices, ethics and experimental design to obtain the best possible results. With human practices the team has reached out to the public by attending different exhibitions, given information meetings and presentations. Furthermore, we have actively used social media to reach out to a broader audience by frequently updating about our progress. Apart from informing the public, we have been in contact with both the Technical Research Institution of Sweden and The Swedish Gene Technology Advisory Board. The purpose was to inform them about our project and to get feedback. With this in mind a pamphlet containing environmental, economic and health values was put together. The safety level of our project was confirmed to be at the lowest risk by the Swedish Work Environmental Authority.

Collaborations are of great importance according to LiU iGEM, not only with authorities but also with other iGEM teams. We have collaborated with other teams by sharing our knowledge about ethics and safety regarding the usage of CRISPR/Cas9 in Chlamydomonas reinhardtii and what needs to be considered in sustainable large-scale productions. Exchange of different protocols, improvement of data and ideas to make goals possible are subjects included in our collaborations.

Problem

The International Panel of Climate Change reported conclusions that human activities over the past 50 years have led to the increase of greenhouse gases such as carbon dioxide, nitrogen oxide and methane (1) resulting in augmentation of the earth's temperature.

Algae biofuels have proven to be a possible substitute for fossil fuels. When utilizing algae there are some obstacles to overcome, for instance improvement and identification of suitable strains as in terms of oil productivity and to insure isolation from other crops (3).

There are plenty of questions concerning this area, and the main focus will be the following:

- How will an increased lipid synthesis be attained without damaging the reproductivity of the algae?

- How could the biodiesel production from our algae be up scaled?

Solution

Our solution to the problem includes the design of a unique DNA construct and the expression of the DNA construct in Chlamydomonas reinhardtii. Before a large-scale production of the product is possible, there are certain hindrances that need to be overcome.

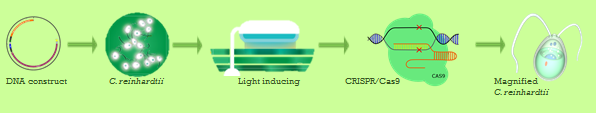

We have been working with the model algae C. reinhardtii into which we have transformed a DNA construct (see figure 1), through Gibson assembly containing; a light inducible promoter LIP, a Cas9 sequence and a sgRNA sequence. These sequences combined result in a knock out of a gene coding for starch synthesis, through the CRISPR/Cas9-system which is induced by the LIP promoter. When the starch production is cut off, the fatty acid synthesis is naturally favored.

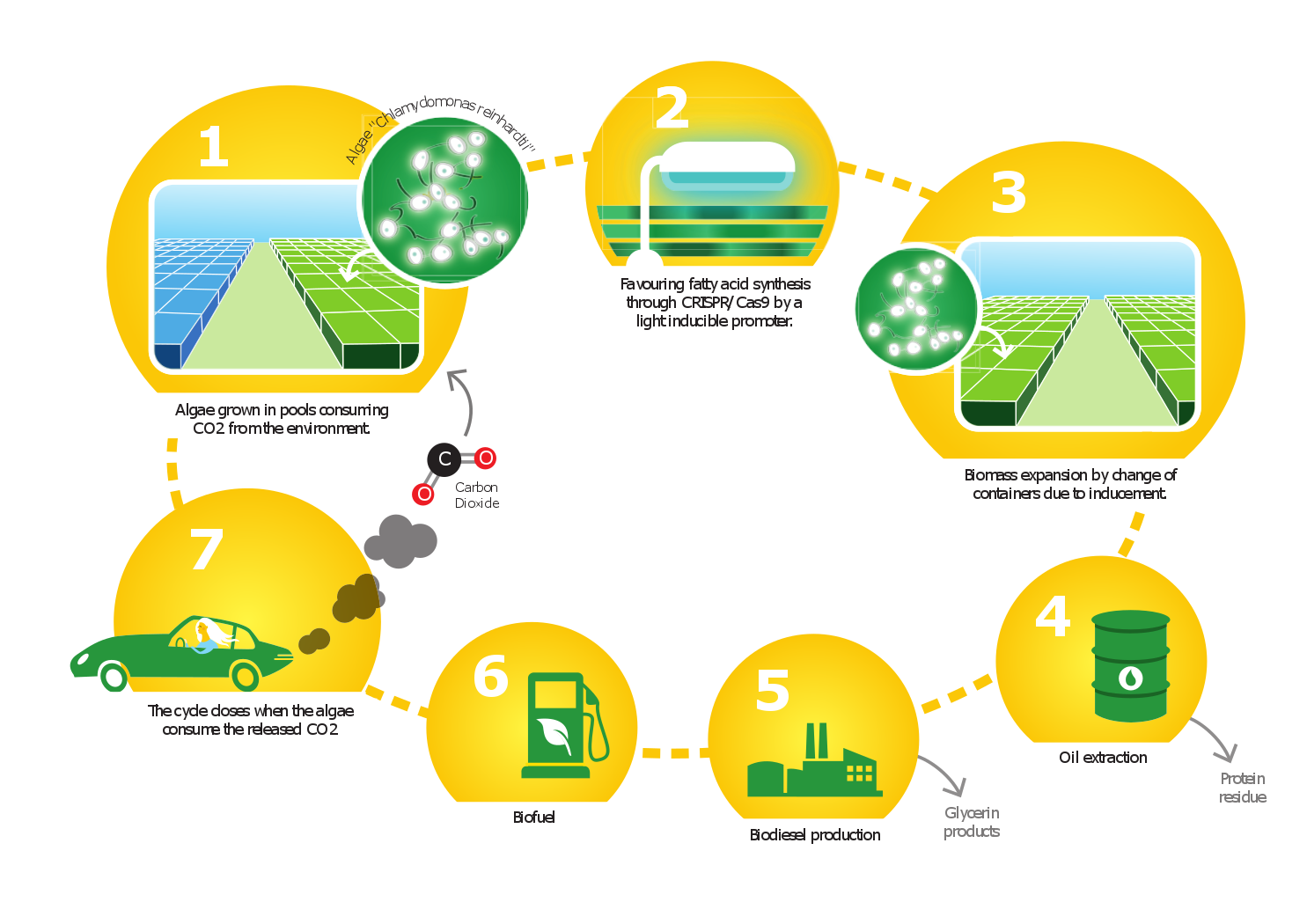

The idea with the project is to enable an economically sustainable production of biodiesel from algae. The production itself is easily described with a cycle of events that we propose. The final event, when the algae consume carbon dioxide from the environment, the production circle is complete, seen below in Figure 2.

The algae are first grown in pools covered by films (step 1 in figure 2) removing high intensity light, preventing the initiation of the CRISPR/Cas9-system. This phase enables the algae to grow to a proper size before being exposed to ultra violet light while streaming through transparent pipes (step 2). The whelming films are removed resulting in an activation of the CRISPR/Cas9 system (step 3). The oil extracted from the algae ('step 4) is later turned into biodiesel (step 5) and is capable to provide our polluted planet with a green alternative for both individuals and the industry (step 7-1). The biodiesel production we could offer would be a helping hand in the long-term substitution of fossil fuels.

Even if the oil extraction (step 4) and the biodiesel production (step 5) techniques are constantly improved there are often residues of protein and glycerin to some extent. Protein residues are mainly used as feeding of fish farms and other animals in the agricultural industry. The residues enrich the food with protein and could also be used as a protein supplement for humans. The glycerin products separated during the biodiesel production (step 5) have a substantial area of use for example in the food industry where the glycerin serves as a sweetener, stabilizer and humectant among others, as well as the pharmaceutical industry when manufacturing drugs with improving smoothness, with humectant and with providing lubrication. New areas of application have recently been found, for instance glycerin has been proven to suppress inflammatory responses in the body.

Assuming that our DNA construct would be expressed successfully the CRISPR-biofuel would not be far away. Large scale production of the biodiesel from C. reinhardtii could be the answer to a sustainable environment in the future.

References

1. NASA - Global Climate Change. A blanket around the Earth. Retrieved 1 Sep. 2016 from: http://climate.nasa.gov/causes/

2. Michael Hannon, Javier Gimpel, Miller Tran, Beth Rasala, and Stephen Mayfield (2010). Biofuels from algae: challenges and potential. US National Library of Medicine National Institutes of Health. PMCID: PMC3152439 http://www.ncbi.nlm.nih.gov/pmc/articles/PMC3152439/

3. Myung, et. al., Effects of dietary substitution of fishmeal with the combined dry microalgae, Nannochloropsis oceanica (NO) biomass residue and casein on growth and body composition of juvenile abalone (Haliotis discus)., 2014 http://www.feednavigator.com/R-D/Residue-of-microalgae-derived-biofuel-could-work-as-fishmeal-alternative-in-aquafeed

4. Fischer Günther and Prieler Syler, Agricultural by-products assicoated with biofuel production chains (report D5.1), 2009

5. The Soap and Detergent Association, Glycerine: an overwiev, http://www.aciscience.org/docs/glycerine_-_an_overview.pdf

6. thechemicalcompany, Global Bonds in Chemistry, Glycerine, 2016, https://thechemco.com/chemical/glycerine/