Introduction

As the engineering sub-team, we had to come up with a project to complement the biologists’ idea of creating a beta carotene-enriched yoghurt using synthetic biology . In order for the yoghurt to be available to low resource countries and communities, we decided it would be a good idea for the yoghurt to be made at consumers’ homes. In such countries like India, where yoghurt is already a staple part of the diet[1], it would make sense for the yoghurt to be made at home, respecting the tradition. Since a fundamental property of yoghurt is that it can be reused to create more batches, a single starter culture of engineered bacteria could potentially last for years if properly reused. So, we came to the idea of creating a simple incubator which could regulate the temperature of the yoghurt at optimum conditions while it is being made, with the capabilities to pasteurise milk prior to incubation. We thought that a solar cooker would be an interesting route to go down for this project.

Design Process

We went through many different prototype ideas on paper in the early stages of the design process. The idea of a solar cooker is actually very simple; a primitive design was a cardboard box painted black on the inside and fitted with aluminium foil reflectors. The reflectors directed the sunlight into the box, which heats up and can be used for cooking. While the principle of solar cookers was simple, it became clear very early on that regulating the temperature of the oven at incubation temperatures was going to be a challenge, since large parabolic solar cookers can reach temperatures of up to 160°C or hotter[2]. So, our main focus was on finding an innovative way to combat this problem in order to design and build a yoghurt maker capable of pasteurising milk.

For instance, we looked into creating an “umbrella” with the supporting structure made of shape memory alloy (SMA) which would deform at incubation temperature to form a shield over the oven to prevent it from heating further. Upon exploring the idea, we discarded this due to the trickiness of engineering SMA materials to deform at a temperature range specific enough to be useful for our application. Not to mention the added costs of such materials!

Another idea would be to design some kind of solar-panel compatible battery, or a diesel generator compatible system. This would be accessible to areas with no electricity but perhaps a community diesel generator. The logistics of this were deemed too complex; it was not known how many communities would have access to diesel generators and whether they would be willing to commit some of their fuel into a yoghurt making tool. The element of unsustainability was also unappealing. So this idea was also discarded.

We were still trying to come up with an idea of how to regulate the temperature of the solar cooker. Drawing inspiration from refrigerators, we looked into using Peltier plates to cool the yoghurt to a reasonable incubation temperature. The thermoelectric effect generated by Peltier plates meant that when electricity flows through the plate, it transfers the generated heat from one side to the other, so one side cools while the other heats up. We hypothesised that the Peltier plates could be used to further cool the yoghurt after the incubation period for storage purposes. While this sounded like a great idea, the costs of implementing Peltier plates into these supposedly accessible and low cost machines was not really feasible. It was found that the efficiency of thermoelectric cooling was only 10%[3]. Furthermore, the limited lifetime of the plates along with the logistics of having a yoghurt maker that would have to be also used as storage meant that a Peltier cooled system was not going to be practical to implement.

A practical solution had to be come up with, so we went back to the original solar oven idea. While we were not able to regulate the internal temperature of a solar cooker, we thought we could use another medium to regulate the heat, such as water. So, we designed a simple feedback control system to regulate the water temperature within the solar cooker system. A three-tiered system was devised; the top “tier” would be a solar collector which would heat water in a reservoir. This tier was connected to the second tier; a smaller solar oven could heat up small increments relatively quickly. The third tier was the yoghurt maker itself, which would essentially be a water bath incubator using water heated in the previous stages to control the temperature at either pasteurisation or incubation temperature for the yoghurt. This design required a feedback system in order to regulate the temperature, so we used an Arduino board.

The tiers were connected by servo motors which would turn on and off to let water through or stop the water flow respectively. A temperature sensor inside the water bath would be set to a reference (i.e. 43C for incubation) and whenever the water bath temperature rose or fell outwith the reference temperature, the servo motor powered valves were opened or closed. We designed the valves ourselves using CAD and got them 3D printed so we could use them to build the system. We used the machine to make yoghurt with some success! Since we could not simulate the same sunny conditions in Glasgow to make the yoghurt with the sun’s energy, we simply poured hot water into the top tier and let the system do the rest of the work. In terms of power, only a small battery would be required to power the Arduino control circuit.

Expert Consultation

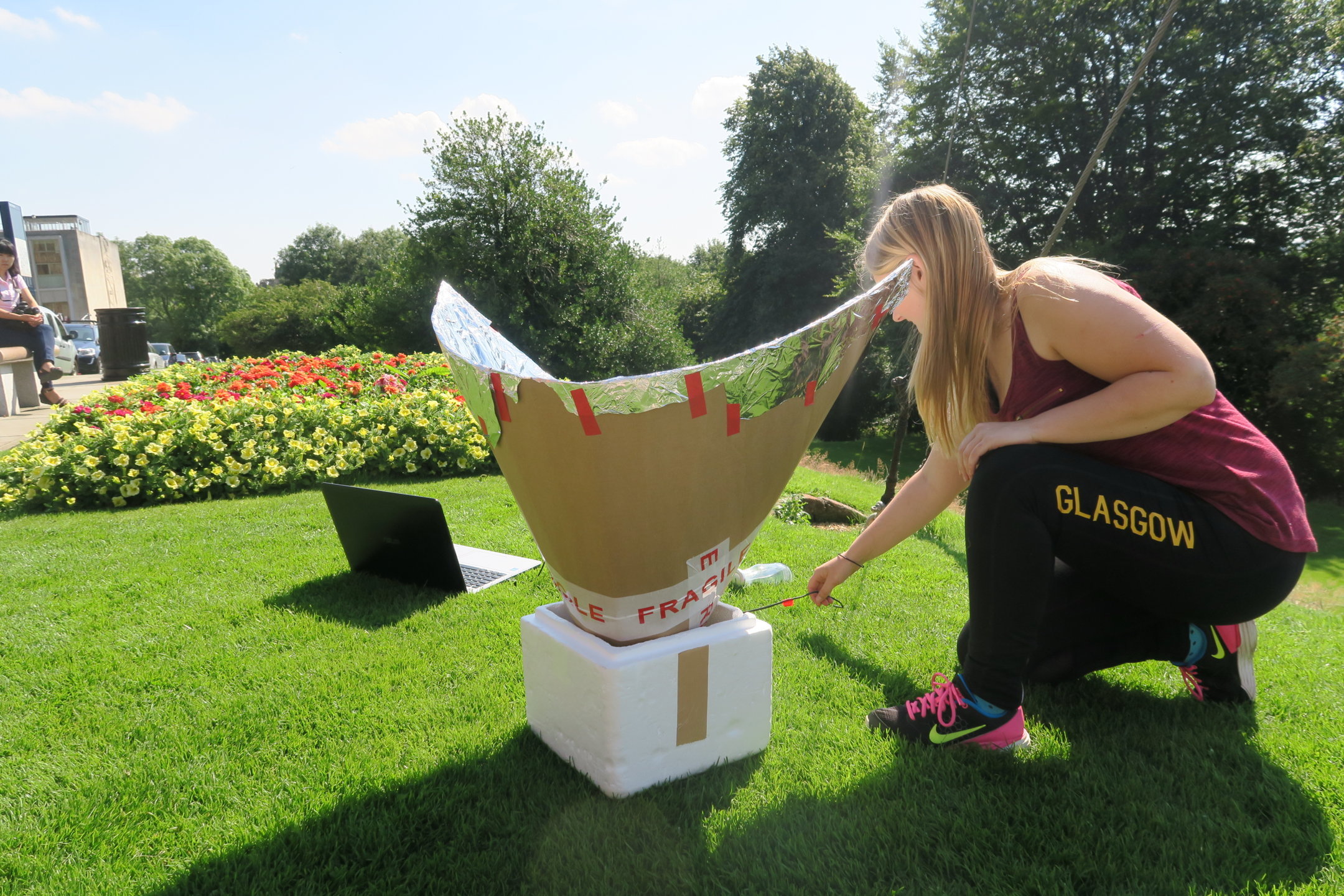

In order to ensure implementing our idea was plausible, we contacted a number of relevant companies, organisations and individuals for advice and feedback. We found there were many organisations for solar cooking, a fact that supported the validity of our idea. We had already deduced that the main problem with solar cooking was that the temperature of a solar oven could not be easily regulated to be cool enough to incubate yoghurt. The optimum temperature for yoghurt incubation was 43C; a solar oven in the sun could reach 150°C or hotter. This fact is used to our advantage in our design to heat the water! In support of this, several individuals on the Solar Cooker World network have claimed that their solar cookers were able to have enough power to boil water. On a sunny day in Glasgow we tested our own rudimentary solar oven, and even in the weak (24C!) Scottish sunshine the water reached 90C, so well over the required pasteurisation temperature. So, we concluded our idea of a solar kettle to heat water would be feasible. Then the water would be used as a controlled water bath, in which a container of yoghurt could be incubated.

In addition to this, we contacted a renewable energy engineer based in India, Dr Srinivasa Chakrawarthy Ravuri. He confirmed that India are “prolific users of solar cookers” and “the weather is eminently suitable for our work”. He also shed some light on Indian culture such as the tradition to boil milk in the morning, which may be tricky as the solar cooker requires strong concentrated sunlight in order to heat the water bath for pasteurising milk. Dr Ravuri was very enthusiastic over our idea and believed it to be possible to implement.

We contacted a company called GoSol and had a conversation over Skype, talking about our design. They gave us pointers on how to improve it and implement it based upon their work and expertise, such as their work in implementing their solar cooking technology in Kenya. They suggested that we should add an attachment part to our design, to make it more multifunctional. In order for our product to be widely accepted it would need a quality of multifunctionality, as a specific low-power yoghurt incubator/pasteuriser would not be useful on its own. GoSol claimed their high power concentrator could boil 10L of water in 20 minutes! If we had a large solar concentrator as an attachment it could broaden the range of uses the incubator has, and then the machine could be used as a community item, as opposed to an individual household machine.

In conclusion, our solar water bath incubator may actually be possible to implement on a community scale. If the strength of the summer sun in Glasgow is sufficient to heat water with our homemade solar collector, it is definitely feasible to work in countries such as India.

References

- ↑ Aneja, R., Mathur, B., Chandan, R., & Banerjee, A. (2002). TECHNOLOGY OF INDIAN MILK PRODUCTS - Handbook on Process Technology Modernization for Professionals, Entrepreneurs & Scientists.

- ↑ Cuce, E., & Cuce, P. M. (2013). Theoretical investigation of hot box solar cookers having conventional and finned absorber plates. Department of Architecture and Built Environment, Faculty of Engineering, University of Nottingham.

- ↑ Brown, D., Fernandez, N., Dirks, J., & Stout, T. (March 2010). The Prospects of Alternatives to Vapor Compression Technology for Space Cooling and Food Refrigeration Applications. Pacific Northwest National Laboratory (PNL). U.S. Department of Energy.