B. Subtilis

General

Bacillus subtilis is a gram-positive bacterium which can be found almost everywhere, especially soil. It can form a protective endospore to resist extreme environmental conditions.

We decided to work in this organism because Bacillus subtilis is a bacteria, which secretes proteins

and enzymes naturally to its surrounding medium.

The goal was to utilise this attribute for enzyme production and create a “cell factory”. Instead of

lysating bacteria, it was desired to have a continuous production of enzymes in a liquid culture that

we can extract from the supernatant.

Repeated inoculations of new bacteria cultures are not necessary because they will stay in the

stationary phase. Only the media has to get replaced.

Bacillus subtilis is classified as a GRAS-organism (general regarded as safe) by the U. S. Food &

Drug administration1 and widely used in S1 laboratories as a model organism. It is also present in

economy as probiotics in pharmacies or fungicide in agriculture.

Furthermore biotechnological industry already uses Bacillus subtilis to synthesize some enzymes.

Usage

For using our product we have different approaches.

Either just using the supernatant to deink our paper fibers or make the time intensive and expensive

step of purificating our enzymes and then proceed with deinking the paper. For purificating we

attached a His-tag on our enzymes and separate them from other components of the supernatant

with nickel columns.

In order to reach the project goals plasmids containing the needed genes had to be transformed into

the bacteria.

We worked with two different Bacillus subtilis strains we got donated by the department of

Pharmaceutical Biotechnology of the Greifswald University, Germany.

We got the wild type strain ATCC 6051 and also the promisingly LS8P-D strain. The LS8P-D stain

is a derivate from the protease-deficient WB800 strain, where two additionally genes got deleted.

The lack of proteases is essential to secrete our enzymes without damaging them.

After trying out multiple protocols we decided to accomplish transformation by electroporation.

The principle of electroporation relies on creating small holes in the cell wall of bacteria, by

sending a current through them. The plasmids enter the bacteria through the holes before the

organism repair them.

The iGEM Team Freiburg and the iGEM Team Bonn collaborated in order to get working transformation protocols for Bacillus subtilis. The resulting manual “How to Bacillus subtilis” can be found on our

Protocol Part

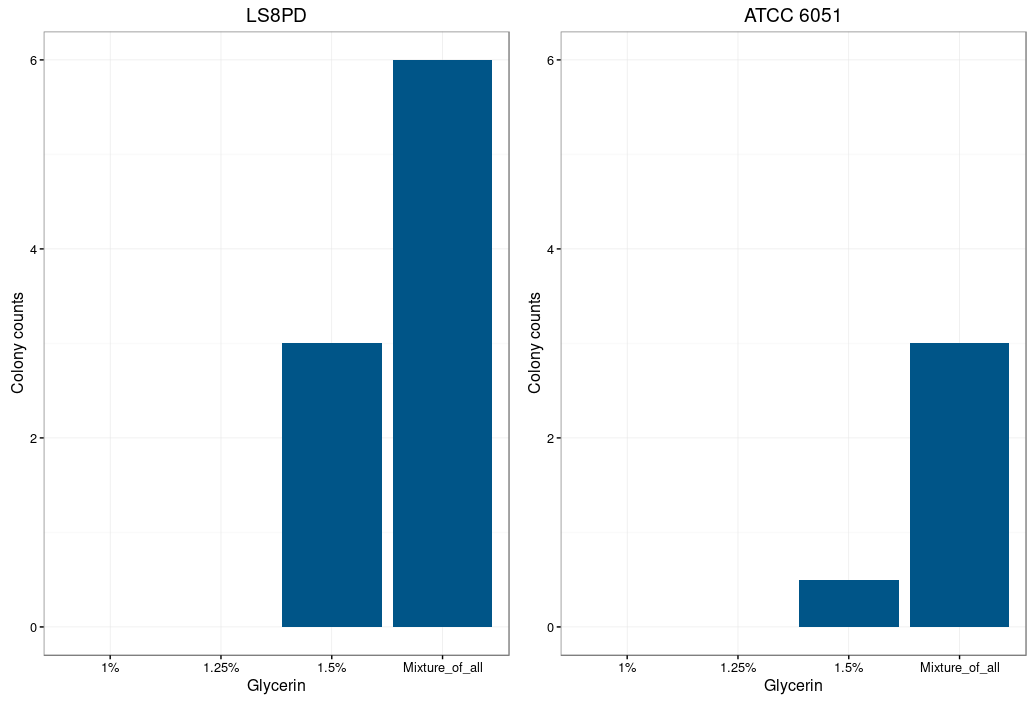

To acquire electrocompetent Bacillus subtilis, the bacteria had to be cultivated overnight in LB medium. 500 μl of the preculture were added to each flask 3x20ml of competency medium (LB medium containing 0.5M Sorbitol) and the cultures were incubated at 37°C 250 rpm shaking till a OD600nm between 0.5 and 0.7/ml was reached. Glycine was added as a weakening agent, replacing the alanine in the cell wall leading to loosen it, for total concentrations of 1%, 1,25% and 1,5% in the different flasks. This was followed by a 60min incubation. The cells got cooled down on ice for 15min and got pelleted through centrifuging at 8500 rpm for 10min at 4°C. The supernatant got poured of and the cell pellet got washed repeatedly through a circle of resuspending, pelleting and discarding of supernatant. The washing steps were performed with washing buffer (0.5M Sorbitol, 0.5M Mannitol and 10% Glycerol). Finally all pellets got combined and resuspended in washing buffer. Aliquots were made and got frozen in liquid nitrogen before stored at -80°C.

Glycine is supposed to act as a weakening agent, through replacing the alanine in cell wall and thereby loosening it 2.

The electroporation worked best with a higher glycine concentration. But a too high concentration will prevent the growth of the bacteria and could also be toxic. The highest colony amount was spotted by using a mixture of all three glycine concentrations (1%,1.25% and 1.5%) for the preparation of electrocompetent cells.

In order to transform the microorganisms, electroporator was used with the fitting cuvettes.

For the electroporation a mix out of plasmid DNA and competent bacteria is done with a volume of

60 μl containing 10ng of DNA per μl. The mixture got cooled on ice for 10 min along with the

electroporation cuvette and then got electroporated on 2,1 kV. 1 ml of competency medium was

used to flush the cells out of the cuvette and the culture was incubated at 37°C 250 rpm shacking for

about 3h before it was plated on LB agar containing kanamycin.

| DNA-concentration (ng/μl) | Number of colonies |

|---|---|

| 10 | 11 |

| 5 | 3 |

| 1 | 1 |

| 0 | 0 |

Table 1. Electroporation efficiency for Bacillus subtilis regarding DNA-concentration.

The table shows the number of formed Bacillus subtilis colonies after the transformation using

electroporation with different amounts of DNA-concentrations. It shows that a higher amount of

DNA (10 ng/μl) leads to a higher number of colonies

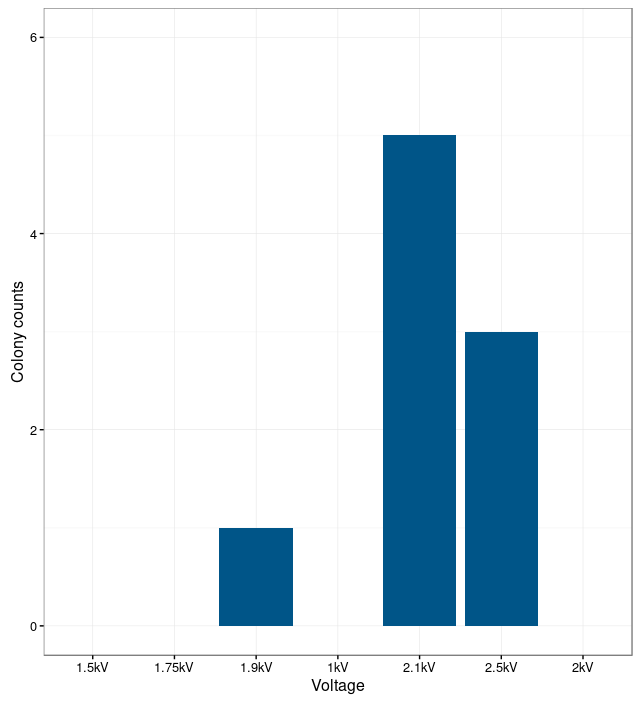

In order to find the best electroporation current, electroporation was performed with different voltages. The electroporation did not work at low currents. The bacteria were not able to take up the plasmids. Is the current getting too high, the bacteria get lysed. The results show the optimal current for the electroporation is at 2.1 kV. At this current the number of successfully transformed bacteria was the highest.

1: http://www.fda.gov/Food/IngredientsPackagingLabeling/GRAS/

2: Zhi Zhang et al.: Development of an Efficient Electroporation Method for Iturin A-Producing Bacillus subtilis ZK