| (24 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

| + | {{:Team:SUSTech_Shenzhen/removeStyles}} | ||

| + | {{:Team:SUSTech_Shenzhen/themeCss}} | ||

| + | {{:Team:SUSTech_Shenzhen/nav}} | ||

| + | {{:Team:SUSTech_Shenzhen/templates/page-header| | ||

| + | url=wiki/images/6/61/T--SUSTech_Shenzhen--LOGO_nowords.png|size=100px| | ||

| + | title=Calibration| | ||

| + | subtitle=Calibration of Flow Speed}} | ||

| + | {{:Team:SUSTech_Shenzhen/main-content-begin}} | ||

| + | |||

= Calibration of fluid flow velocity = | = Calibration of fluid flow velocity = | ||

| − | To visualize the flow profile, rainbow beads (diameter:) were dissolved in the cell culture medium, which | + | To visualize the flow profile, rainbow beads (SPHERO<sup>TM</sup> Rainbow Calibration Particles, Cat No. RCP-60-5, Lot No. AB01, diameter: 6um<ref>{{SUSTech_Shenzhen/cite web | url=http://www.spherotech.com | title= Rainbow beads official website}}</ref>) were dissolved in the cell culture medium, which contained some dead cells. A series of pumped flow rate(5μl/min, 15μl/min, and 45μl/min) were applied to generate a steady fluid flow. The length of the streakline (shown as a gray line in picture) represents the total traveling distance of the beads during the exposure time of 100ms . Fig. 1 shows a typical image of a bead trace(fastest microfluidics channel with the flow rate of 5ul/min). To minimize hydraulic effects of the PDMS walls, the pictures were taken from the midplane of the channel providing the maximum flow velocity. Note that the traveling direction of the beads was left. Each streak was measured separately, and the average length of all streaks in one particular channel divides the exposure time was regarded as the maximum flow velocity of this channel. <ref>Maneshi MM, Sachs F, Hua SZ, ''A Threshold Shear Force for Calcium Influx in an Astrocyte Model of Traumatic Brain Injury.''J Neurotrauma. 2015 Jul 1, '''32'''(13) : p. 1020-9. </ref> |

| − | Fig. | + | {{SUSTech_Image | filename=T--SUSTech_Shenzhen--DB56D45F-D056-4A82-897A-2CE77C2C4A12.png | caption='''Fig.1 Bead Trace in The Fastest Microfluidics Channel with The Flow Rate of 5ul/min''' | width=1000px}} |

| + | == Experiment == | ||

| + | To minimize the error, we took pictures on fast microfluidics channel when pumped flow rate was 5μl/min; on mid microfluidics channel when pumped flow rate was 15μl/min; on slow microfluidics channel when pumped flow rate was 45μl/min, considering that fluid flow velocity is proportional to pumped flow rate. | ||

| − | + | Data collection blow: | |

| − | + | {| class="table table-striped" | |

| − | {| class= | + | ! channel !! flow rate(μl/min) !! length①(um) !! length②(um) !! length③(um) |

| − | ! channel !! | + | |

|- | |- | ||

| − | + | | fast || 5 || 630 || 455 || 610 | |

|- | |- | ||

| − | + | | mid || 15 || 180 || 160 || 180 | |

|- | |- | ||

| − | | slow || | + | | slow || 45 || 48 || 75 || 80 |

|} | |} | ||

| − | + | == Result == | |

| − | We wrote a MatLab program to calculate the | + | We wrote a MatLab program to calculate the maximum flow velocities. Codes were shown below: |

| − | + | <html><div class="bs-callout bs-callout-info"> | |

| − | < | + | <h4>MatLab Code:</h4> |

| − | ex_fast=[630,455,610]*90; % align the data to um/s by multiply 10 and to | + | <p> |

| − | + | ex_fast=[630,455,610]*90; | |

| + | </p><p> | ||

| + | % align the data to um/s by multiply 10 and convert to 45μl/min | ||

| + | </p><p> | ||

ex_mid=[180,160,180]*30; | ex_mid=[180,160,180]*30; | ||

| − | + | </p><p> | |

ex_slow=[48,75,80]*10; | ex_slow=[48,75,80]*10; | ||

| − | + | </p><p> | |

ex_fast_mean=mean(ex_fast); ex_fast_std=std(ex_fast); | ex_fast_mean=mean(ex_fast); ex_fast_std=std(ex_fast); | ||

| − | + | </p><p> | |

ex_mid_mean=mean(ex_mid); ex_mid_std=std(ex_mid); | ex_mid_mean=mean(ex_mid); ex_mid_std=std(ex_mid); | ||

| − | + | </p><p> | |

ex_slow_mean=mean(ex_slow); ex_slow_std=std(ex_slow); | ex_slow_mean=mean(ex_slow); ex_slow_std=std(ex_slow); | ||

| − | </ | + | </p> |

| + | </div> | ||

| + | </html> | ||

| + | Note: ex_fast_mean is the mean value of maximum flow velocity of fast microfluidics channel when pumped flow rate is 45μl/min, ex_fast_std is its standard deviation, et cetera. | ||

| − | + | {| class="table table-striped" | |

| − | + | ! variable !! mean(um/s) !! variable !! std(um/s) | |

| − | + | ||

| − | + | ||

| − | {| class= | + | |

| − | ! variable !! mean( | + | |

|- | |- | ||

| − | + | | ex_fast_mean || 50850 || ex_fast_std || 8600 | |

|- | |- | ||

| − | + | | ex_mid_mean || 5200 || ex_mid_std || 350 | |

|- | |- | ||

| − | | ex_slow_mean || 676 | + | | ex_slow_mean || 676 || ex_slow_std || 170 |

|} | |} | ||

| − | + | The ratio of maximum velocities in 3 different channels is 13:100:978. | |

| − | Fig. | + | {{SUSTech_Image | filename=T--SUSTech_Shenzhen--855C7E02-2E51-441A-9492-A2B281185010.png | caption='''Fig.2 Maximum Velocities in Each Channel with The Flow Rate of 45ul/min''' | width=1000px}} |

= Reference = | = Reference = | ||

| − | < | + | <references/> |

| + | |||

| + | {{:Team:SUSTech_Shenzhen/main-content-end}} | ||

| + | {{:Team:SUSTech_Shenzhen/wiki-footer}} | ||

| + | {{:Team:SUSTech_Shenzhen/themeJs}} | ||

Latest revision as of 12:10, 19 October 2016

Calibration

Calibration of Flow Speed

Calibration of fluid flow velocity

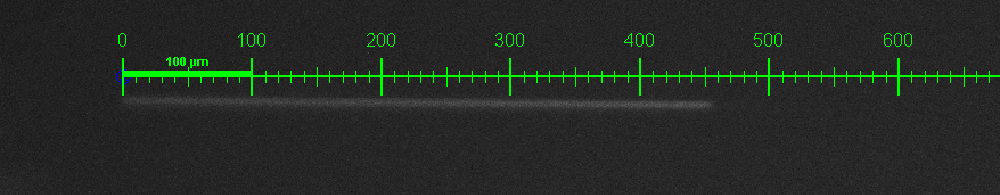

To visualize the flow profile, rainbow beads (SPHEROTM Rainbow Calibration Particles, Cat No. RCP-60-5, Lot No. AB01, diameter: 6um[1]) were dissolved in the cell culture medium, which contained some dead cells. A series of pumped flow rate(5μl/min, 15μl/min, and 45μl/min) were applied to generate a steady fluid flow. The length of the streakline (shown as a gray line in picture) represents the total traveling distance of the beads during the exposure time of 100ms . Fig. 1 shows a typical image of a bead trace(fastest microfluidics channel with the flow rate of 5ul/min). To minimize hydraulic effects of the PDMS walls, the pictures were taken from the midplane of the channel providing the maximum flow velocity. Note that the traveling direction of the beads was left. Each streak was measured separately, and the average length of all streaks in one particular channel divides the exposure time was regarded as the maximum flow velocity of this channel. [2]

Experiment

To minimize the error, we took pictures on fast microfluidics channel when pumped flow rate was 5μl/min; on mid microfluidics channel when pumped flow rate was 15μl/min; on slow microfluidics channel when pumped flow rate was 45μl/min, considering that fluid flow velocity is proportional to pumped flow rate.

Data collection blow:

| channel | flow rate(μl/min) | length①(um) | length②(um) | length③(um) |

|---|---|---|---|---|

| fast | 5 | 630 | 455 | 610 |

| mid | 15 | 180 | 160 | 180 |

| slow | 45 | 48 | 75 | 80 |

Result

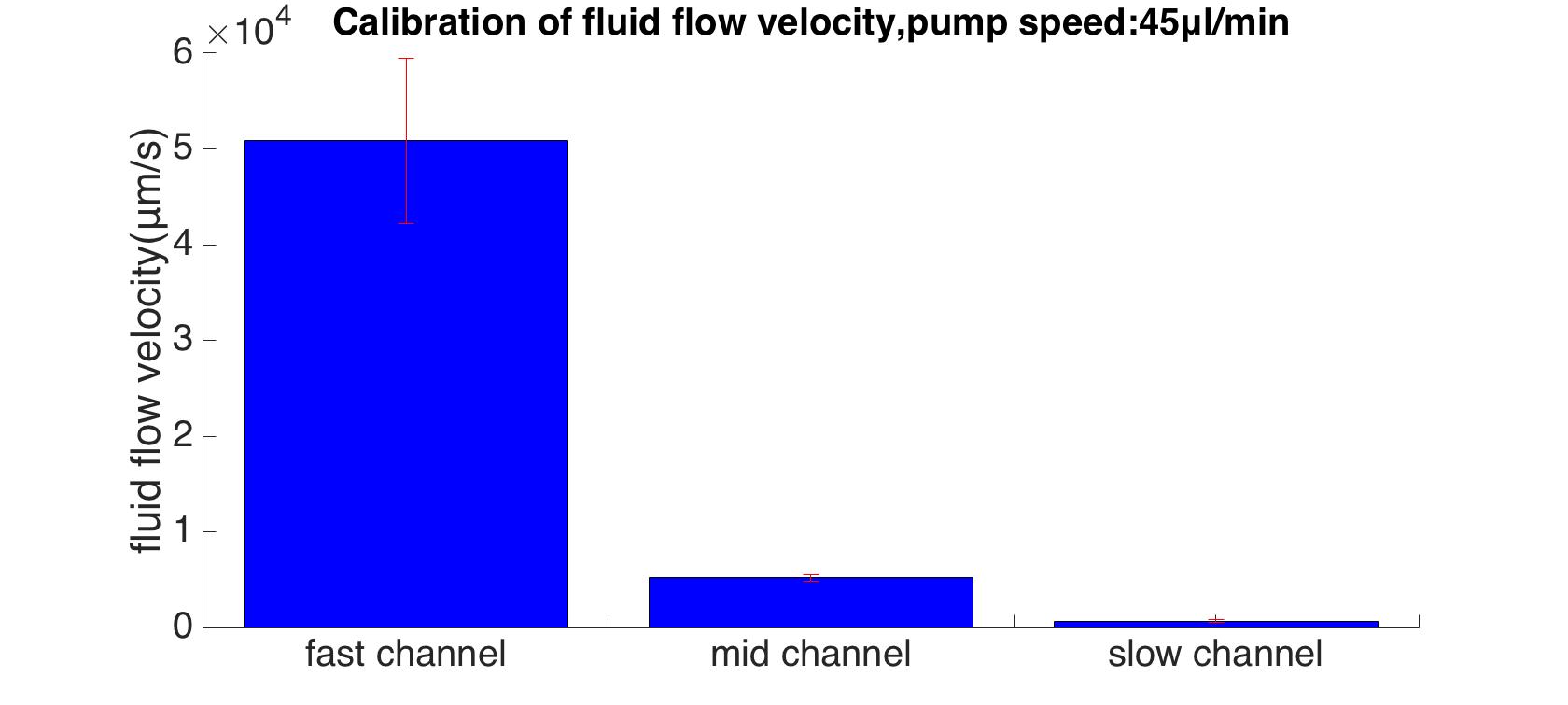

We wrote a MatLab program to calculate the maximum flow velocities. Codes were shown below:

MatLab Code:

ex_fast=[630,455,610]*90;

% align the data to um/s by multiply 10 and convert to 45μl/min

ex_mid=[180,160,180]*30;

ex_slow=[48,75,80]*10;

ex_fast_mean=mean(ex_fast); ex_fast_std=std(ex_fast);

ex_mid_mean=mean(ex_mid); ex_mid_std=std(ex_mid);

ex_slow_mean=mean(ex_slow); ex_slow_std=std(ex_slow);

| variable | mean(um/s) | variable | std(um/s) |

|---|---|---|---|

| ex_fast_mean | 50850 | ex_fast_std | 8600 |

| ex_mid_mean | 5200 | ex_mid_std | 350 |

| ex_slow_mean | 676 | ex_slow_std | 170 |

The ratio of maximum velocities in 3 different channels is 13:100:978.

Reference

- ↑ Rainbow beads official website, Retrieved from http://www.spherotech.com.

- ↑ Maneshi MM, Sachs F, Hua SZ, A Threshold Shear Force for Calcium Influx in an Astrocyte Model of Traumatic Brain Injury.J Neurotrauma. 2015 Jul 1, 32(13) : p. 1020-9.