Javier.luna (Talk | contribs) |

Javier.luna (Talk | contribs) (→Results: Polymerization experiments) |

||

| Line 71: | Line 71: | ||

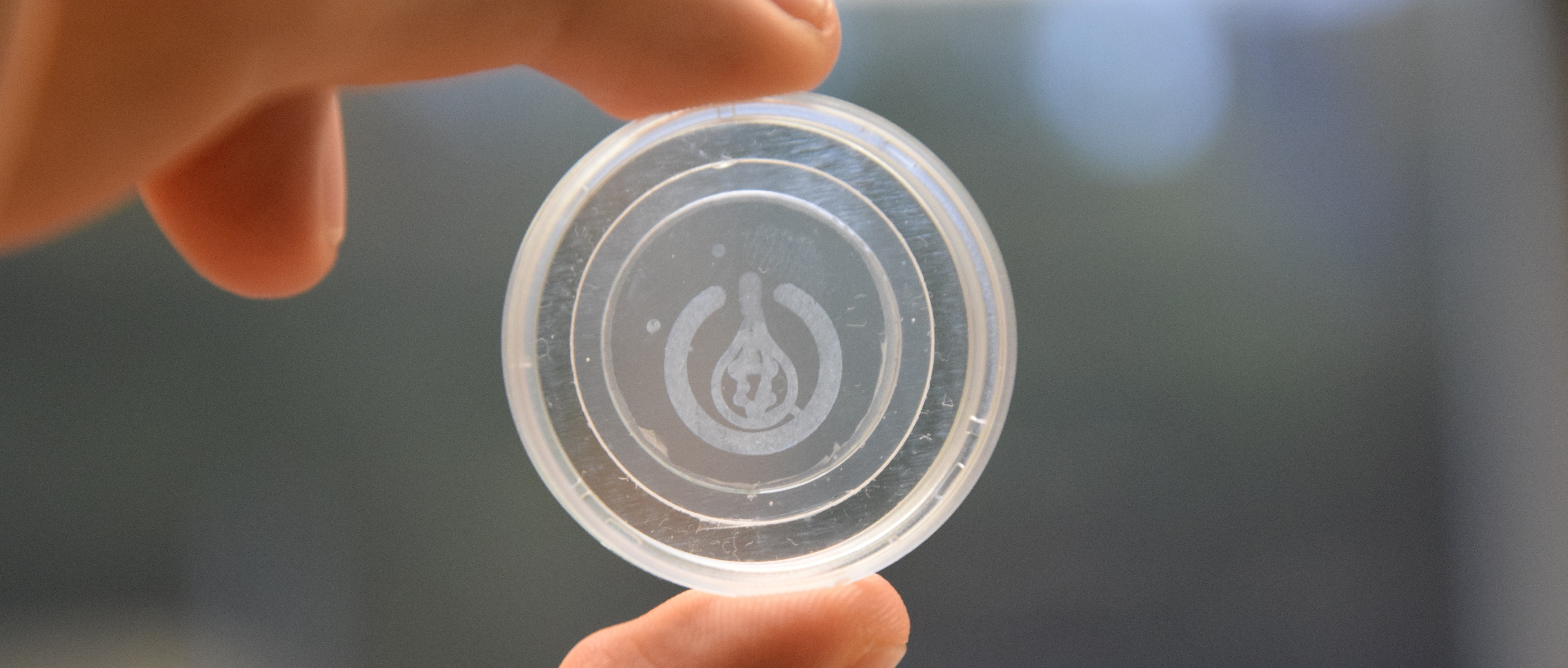

[[Image:Muc16_Bioprinter_TUMDruck.jpeg |frameless|left|450px| <i><b>Figure 5:</b></i> Look at what we have got: Our university logo printed with biotin receptor expressing cells of biotinylated ibidi-slides]] | [[Image:Muc16_Bioprinter_TUMDruck.jpeg |frameless|left|450px| <i><b>Figure 5:</b></i> Look at what we have got: Our university logo printed with biotin receptor expressing cells of biotinylated ibidi-slides]] | ||

| − | The next step was the actual printing of our cells in the stretavidin medium to observe if the printed stucture is stable enough so that we can see the printed picture. | + | The next step was the actual printing of our cells in the stretavidin medium to observe if the printed stucture is stable enough so that we can see the printed picture. |

| + | |||

| + | The comparission between the upper pictures in fig. X, which correspond to PBS in the reservoir and the lower ones with Streptavidin (11.4 mg/ml) in the reservoir, clearly shows that streptavidin is necessarry for our polymerization experiment. Suprisingly biotinyliated BSA or PAS-Lysine are mandatory for polymerisation. Neither cells (fig. X d), nor GFP (fig. X f) on its own are sufficient. By directly comparing the sample in fig. X b with the one in fig. X h we stated that both linker proteins either BSA or PAS-Lysine work quite good. The comparision of fig. Xb with fig. Xj shows that pre-polymerization with a small amount of Streptavidin improves the stability of the polymer, nethertheless it is not mandatory. Directly printing in a Streptavidin reservoir is sufficient for polymerization. | ||

| + | |||

| + | |||

| + | All in all we developed a recipe for the „perfect saucage“ we called it: | ||

| + | • 6/10 volume parts biotinylated BSA, 11 mg/ml or biotinylated PAS-Lysin 10 mg/ml | ||

| + | • 0.5/10 volume parts biotinylated GFP | ||

| + | • 4/10 volume parts gravity sedimented scAvidin-cells | ||

| + | |||

| + | |||

| + | Before filling it into our printer we did some experiments to prove the stability and ability to print in a precice manner. We were absolutely thrilled by the stability and integrity of our polymer. In fig. X we pipetted the recipe given above (with trypane blue for visualisation) into a Streptavidin solution of 11.4 mg/ml and were able to paint with our protein-cell-polymer. In the video above we shaked the polyer without any negative influence on the stability. | ||

| + | Next we asked wether we were just polymerizing protein or if our receptor construct is functional and our cells are „sticky“. Therefore we needed to see that the avidinylated cells attach to the biotinylated GFP/BSA polymer. We drawed some lines of our „perfect saussage“ recipe into Streptavidin solution and watched the polymer under the microscope. Here were saw a well structured shape with cells in it (fig. X). Upon heavyly shaking the microscopy slide the polyer is shaking from side to side but not breaking and most interestingly: the cells are shaking with the polymer but not droping out of it. | ||

| + | |||

| + | Finally we managed to transfer all these experiments into practice: we printed the TUM logo (fig. X) and our own logo (fig. X) with a ink made of biotinylated proteins and cells! | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | Discussion | ||

| + | |||

| + | GFP is carrying 13 surface lysine that can be biotinylated nethertheless it seems to need the hydrophobicity of PAS or BSA for efficient polymerisation. The need for a protein matrix that binds the avidinylated cells might be a technical one, because the cells are too far away from each other to build any contcatcs when leaving the syringe. Further optimization needs to be done to reach a sufficient cell density and flow-through speed. | ||

Revision as of 02:59, 20 October 2016

Design: Why we chose the Avidin & Biotin affinity pair

We have discussed a long time what kind of biochemical interaction we could use to have a rapid and high-affinity interaction of the components. Factors that influenced our choice were: affinity (KD), association rate (kon) as well as the number of binding sites we can have on a recombinant protein as well as the yield it gives when produced recombinantly. The comparison with some other possible affinity-pairs is shown in the following table.

| Affinity pair | Kind of interaction | Dissociation constant | Association rate |

| Avidin - Biotin | non covalent | 10-15M [1] | 55 440 |

| SpyCatcher - SpyTag | covalent | not applicable | far too slow for rapid polymerization |

| StrepTactin - Strep-tag II | non covalent | ~10-6M[2] | affinity is too low for a constant interaction |

Multivalency and avidity as major principles for polymerization

A nice point about the biotin - Avidin affinity pair is that biotin groups can be conjugated to any protein of choice that contains surface-exposed aminogroups. In the next line we have visualized aminogroups in two proteins that we have used in our project as they are available in big amounts: enhanced Green Fluorescent Protein (eGFP, left) and Bovine Serum Albumine (BSA, right)

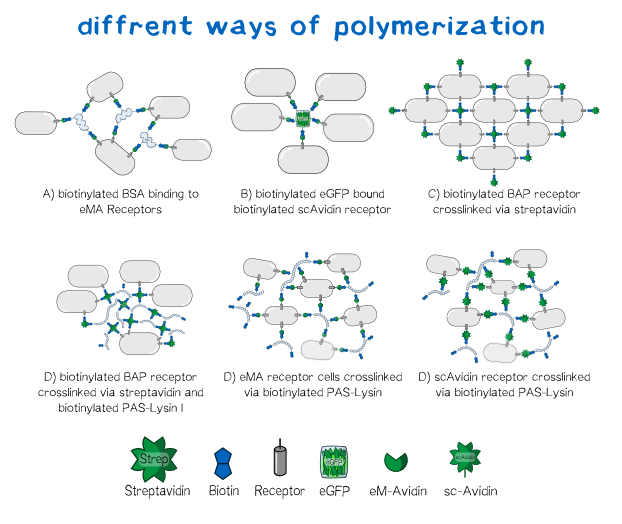

Different polymers possible with biotINK polymerization

Since the foundation of our polymerization reaction is the interaction of Streptavidin and its binding partner Biotin (Referenz) we used biotinylated polymers to convery the polymerization between the cells.

Results: Polymerization experiments

Creating the perfect mesh

In order to characterize our cells concerning their biotin binding capabilities by taking a look at their polymerization behaviour after adding them to a medium, which is rich of biotinylated protein linkers.

Since the expression of the two biotin binding receptor constructs was significantly higher than the expression of the biotin presenting one, we mainly used one of the biotin binding constructs, the scAvidin version. The main idea behind the polymerization experiments was that we wanted to find the perfect conditions for the cells to stick together, concerning the right medium, concentration and biotinylation degree of the protein linker.

The main components of all our polymerization experiments were svAvidin-construct-transfected Trex cells, biotinylated bovine serum albumine and streptavidin (or streptactin).

Our first experiments were not conducted with our printer, but under a fluorescence microscope for better analysability of the produced polymer.

The tests showed that the polymerization effect is only dependent on three things:

- cell density in the biotINK

- concentration of biotinylated BSA in the biotINK

- concentration of Streptavidin inside the printing medium

Since the addition or removal of biotinylated eGFP from the ink did not show a significant effect on then polymerization it was added to every sample for better visualization.

Experiments showed that the concentration of biotinylated BSA in our biotINK is the limiting factor for polymerization. The Higher the concentration of BSA was, the more structural integrity of the "printed" polymer could be oberved.

To see how well our printer performs with cells we wanted to test the interaction of the scAvidin transfected cells with biotinylated surfaces. For this reason we coated an ibidi-slide with poly-D Lysin for the following biotinylationwhich was then biotinylated. The cells were printed on the surface to observe, if the cells stick to the surface and are held in the right position so that the piture that is printed can be seen on the ibidi-slide. The first experiments showed that the interaction was present (Fig.x) and the results looked very satisfying.

The next step was the actual printing of our cells in the stretavidin medium to observe if the printed stucture is stable enough so that we can see the printed picture.

The comparission between the upper pictures in fig. X, which correspond to PBS in the reservoir and the lower ones with Streptavidin (11.4 mg/ml) in the reservoir, clearly shows that streptavidin is necessarry for our polymerization experiment. Suprisingly biotinyliated BSA or PAS-Lysine are mandatory for polymerisation. Neither cells (fig. X d), nor GFP (fig. X f) on its own are sufficient. By directly comparing the sample in fig. X b with the one in fig. X h we stated that both linker proteins either BSA or PAS-Lysine work quite good. The comparision of fig. Xb with fig. Xj shows that pre-polymerization with a small amount of Streptavidin improves the stability of the polymer, nethertheless it is not mandatory. Directly printing in a Streptavidin reservoir is sufficient for polymerization.

All in all we developed a recipe for the „perfect saucage“ we called it:

• 6/10 volume parts biotinylated BSA, 11 mg/ml or biotinylated PAS-Lysin 10 mg/ml

• 0.5/10 volume parts biotinylated GFP

• 4/10 volume parts gravity sedimented scAvidin-cells

Before filling it into our printer we did some experiments to prove the stability and ability to print in a precice manner. We were absolutely thrilled by the stability and integrity of our polymer. In fig. X we pipetted the recipe given above (with trypane blue for visualisation) into a Streptavidin solution of 11.4 mg/ml and were able to paint with our protein-cell-polymer. In the video above we shaked the polyer without any negative influence on the stability.

Next we asked wether we were just polymerizing protein or if our receptor construct is functional and our cells are „sticky“. Therefore we needed to see that the avidinylated cells attach to the biotinylated GFP/BSA polymer. We drawed some lines of our „perfect saussage“ recipe into Streptavidin solution and watched the polymer under the microscope. Here were saw a well structured shape with cells in it (fig. X). Upon heavyly shaking the microscopy slide the polyer is shaking from side to side but not breaking and most interestingly: the cells are shaking with the polymer but not droping out of it.

Finally we managed to transfer all these experiments into practice: we printed the TUM logo (fig. X) and our own logo (fig. X) with a ink made of biotinylated proteins and cells!

Discussion

GFP is carrying 13 surface lysine that can be biotinylated nethertheless it seems to need the hydrophobicity of PAS or BSA for efficient polymerisation. The need for a protein matrix that binds the avidinylated cells might be a technical one, because the cells are too far away from each other to build any contcatcs when leaving the syringe. Further optimization needs to be done to reach a sufficient cell density and flow-through speed.

Sticky cells in the Micromanipulator

To get a clearer view on how the cells polymerize we wanted to see the actual polymerization event and how the cells stick to each other. In order to do so we used a micromanipulator for ejection of single cells. We compared the ejection of our biotINK in Streptavidin solution with the ejection in phosphate buffered saline (negative controle) to make sure that, if polymerization occures, it is because of an specific interaction of the cells with biotinylated BSA and streptavidin.

It was very interesting to see that there really is a difference between the two experiments in a way that the biotINK, ejected in streptavidin, contrary to the one ejected in PBS, does show polymerization of cells.

References