Interaction of biotin and Streptavidin leads to a pseudopolymerization

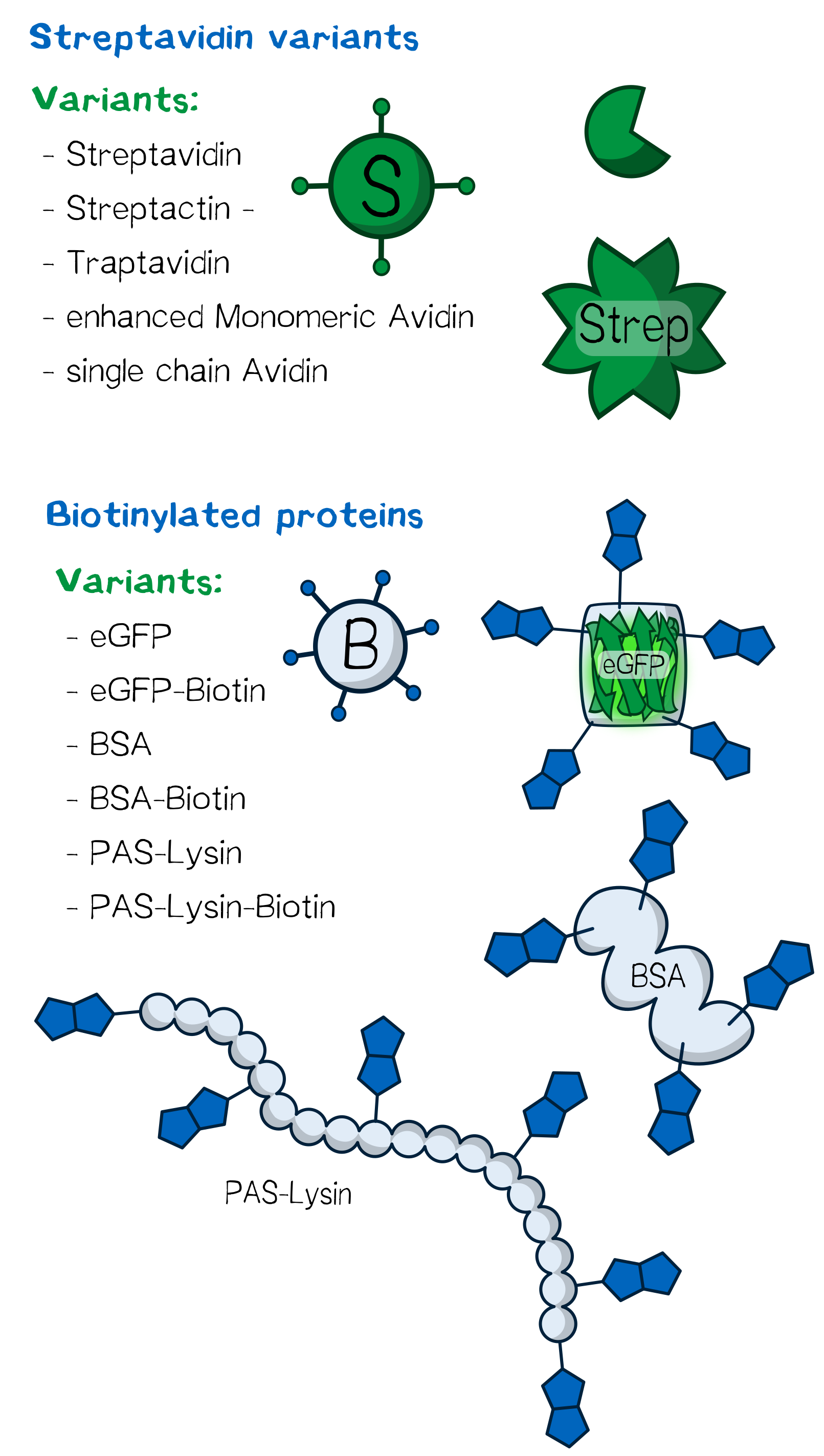

We use the extraordinary strength of the biotin:streptavidin binding for linking genetically engineered cells with streptavidin. The cells express a receptor which allows them to present a biotin molecule or a streptavidin variant on their cell surface (link receptor construct).

The tetrameric Protein itself is able to cross link the biotinylated cells and form a stable network. A linker molecule like biotinylated PAS-Lysin, however, might increase the stability of the cell structure due to its multiple biotinylation sites.

Streptavidin and Biotin: The strongest non-covalent affinity in nature

Streptavidin is a tetrameric protein with a molecular weight of 52.8 kDa[1] originally found in Streptomyces avidinii. Each subunit is able to bind one biotin molecule (molecular weight = 244.3 Da). This specific, non-covalent bondage with a femto molar dissociation constant (kD = 10-15 M) is one of the strongest known biological affinities. Antibodies, in comparison, have dissociation constants in the range of 10-7 – 10-11 M.

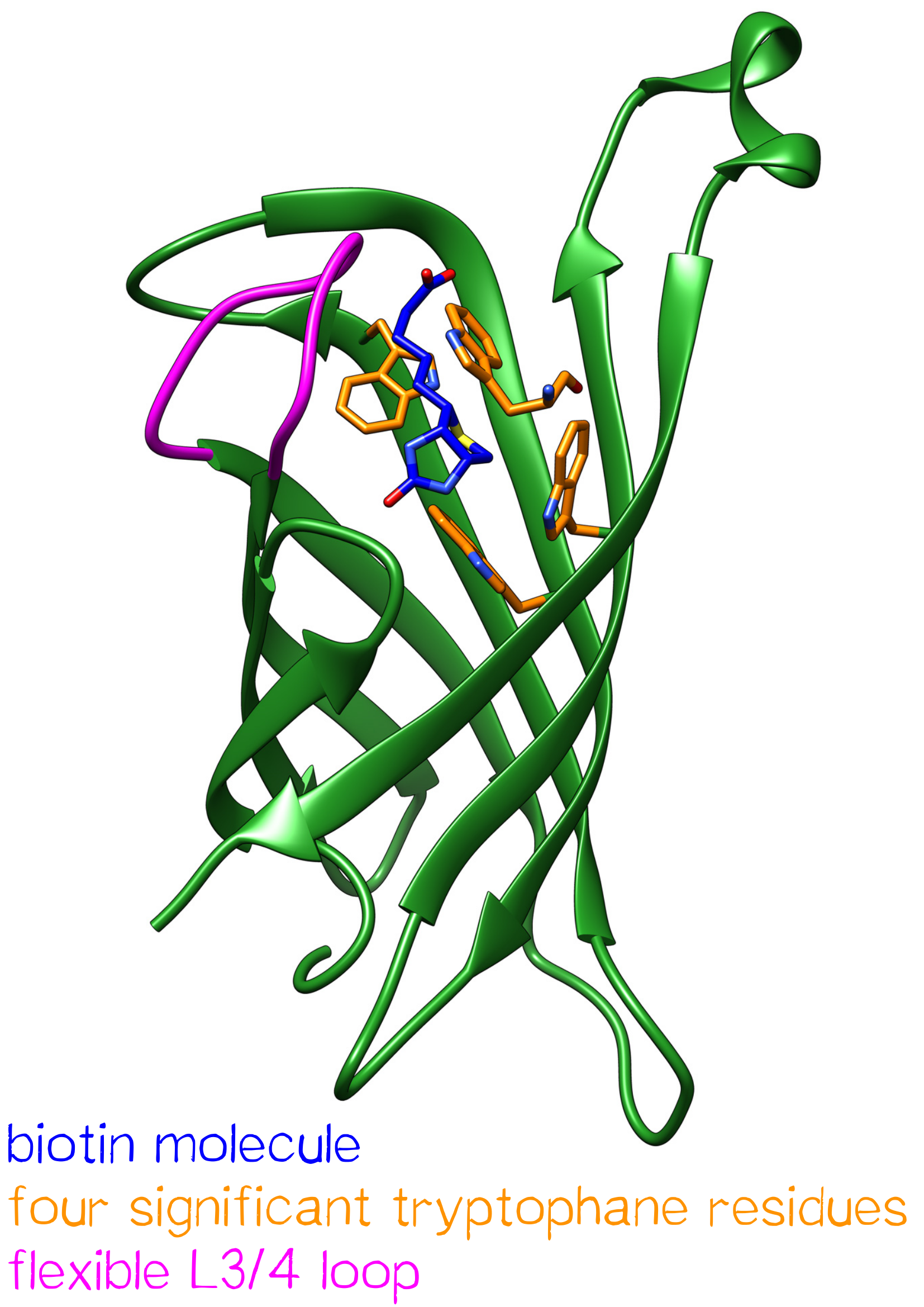

One subunit of streptavidin is organized as an eight stranded antiparallel beta sheet of coiled polypeptide chains which form a hydrogen bonded barrel with extended hydrogen loops[2] (see figure 2).

The biotin binding pocket consists of primarily aromatic or polar side chains, these interact with the hetero atoms of biotin.

Due to its low unspecific binding, Streptavidin is primarily used for protein-purification via affinity chromatography and as a detection and coupling reagent in dayly lab routine.

The rapid and very strong linkage is generally due to multiple hydrogen bonds as well as van der Waals interactions. Comparing apostreptavidin and the streptavidin-biotin complex shows several structural differences of the binding pocket.

The ordering of a flexible surface polypeptide loop results in burying the biotin molecule in its pocket. Without biotin the L3/4 loop is disordered and does not give clear electron density, it closes upon biotin binding.[3].

Important for the high barrier of dissociation are biotin-tryptophan contacts in the binding pocket. There are four significant tryptophan residues involved in the binding site. Three of those (Trp79, Trp92 and Trp108) are lined up in one section. Trp120 binds the biotin molecule from an adjacent subunit and displays a much larger influence in binding free energy[4].

Moreover the hydrogen bonding network and van der waals interactions show great influence in binding free energy. Compared to similar hydrogen bonding donors and acceptors of other protein-ligand systems the hydrogen bonding of Streptavidin to the ureido oxygen of biotin is remarkably high.

Streptavidin variantes and homologes

| protein | residues | molecular weight monomer [kDa] | molecular weight tetramer [kDa] | theoretical pI | pI (IEF) | extinction coefficient (monomer, A280) [M-1 cm-1] |

| Streptavidin wt | 126 | 13.20 | 52.80 | 6.09 | 41940 | |

| Traptavidin | 126 | 13.13 | 52.52 | 5.14 | 41940 | |

| Strep-Tactin | 126 | 13.24 | 52.52 | 8.32 | 41940 | |

| enhanced monomeric Avidin | 138 | 15.22 | / | 5.91 | 35075 | |

| single chain Avidin | 567 | 61.53 | / | 9.84 | 94460 |

Traptavidin - increased mechanical strength of the biotin binding

The streptavidin mutant (S52G, R53D) shows a 10 times lower dissociation constant (KD= 10-16 M)compared to the wildtype. Moreover, the tetramer has improved thermostability before splitting into monomers (~10 °C higher)[5]. In contrast to streptavidin, the Traptavidin L3/4 loop (residues 45-50) does not change its conformation upon binding biotin. The binding pocket is already closed and lacks flexibility. The loss of a structural change may lower the entropic cost of binding and decreases dissociation. The traptavidin:biotin dissociation at pH 7.4 is significantly slower than streptavidin:biotin dissociation. Both proteins have comperable length of biotin binding hydrogen bonds.

Strep-Tactin - an engineered streptavidin variant, which can bind specifically to the strep tag

The sequence of this affinity tag is eight residues long and can be genetically fused N- or C-terminal to recombinant protein. Using the Strep tag:Strep-Tactin-System for affinity chromatography enables a simple and rapid one step-purification and provides great yields in protein- or protein complex purification. The strep-tagged protein binds Strep-Tactin, which is immobilized on the column matrix. After removing host proteins by washing, the target protein can be eluted with desthiobiotin, which binds the Strep-Tactin several orders of magnitude stronger. Over the years both, the Strep tag and the Streptavidin were optimized resulting in strep tag II (WSHPQFEK)and Strep-Tactin [6]

Enhanced Monomeric Avidin (eMA)- engineered for applications like molecular labelling

Due to its monovalent nature unwanted cross-linking of biotin conjugats can not occur.

Streptavidin binding pockets depend on one residue from a adjacent subunit, thus binding affinity of a single subunit is decreased (KD = 10-7 to 10-9 M). eMA consists of a monomerized Rhizavidin dimer, which contains a disulfid bond in the binding site restraining the protein and forming a rigid binding pocket[7].

Single chain avidin (scAvidin)

Production and purification of streptavidin

The minimal Streptavidin wildtype gene is cloned on a pSA plasmid. The transcription is under control of a T7-promoter. The E.coli BL-R (DE3) strain codes the T7-polymerase under the control of a lacUV5 promotor, which can be induced by Isopropyl β-D-1-thiogalactopyranoside (IPTG).

A shaking flask with 2 L LB medium supplemented with ampicillin is inoculated 1:40 with a 50 ml preculture grown at 30 °C over night.

The bacterial culture shakes at 37 °C for a few hours until its optical density reaches 0.6 and protein production is induced with 1 mM IPTG. After 4 hours the cells can be harvested by centrifugation (5000 rpm for 20 min).

The cell pellet is resuspended in a 20 mM Tris/HCl buffer (500 mM NaCl, pH 8) and Homogenization can be proceeded with French press or PANDA. The cell lysate is centrifuged at 11500 rpm for 30 min to separate the inclusion bodies in the pellet from the soluble proteins of the supernatant.

The inclusion bodies consist of aggregated and misfolded protein, those are denaturated with 6 M guanidinium chloride and centrifuged at 15000 rpm for 15 minutes.

The aggregations in the pellet are discarded and the supernatant is added slowly into a high volume of PBS (30 ml PBS for 1 ml protein solution) and incubated over night. Guanidinium chloride is diluted and proteins are able to fold correctly.The solution is centrifuged again (11500 rpm for 30 min) to remove aggregates.

The Streptavidin purification is proceeded by fractionally ammonium sulfate precipitation. After each precipitation step the solution is incubated without stirring for few hours and centrifuged at 11500 rpm for 30 minutes afterwards.

The first precipitation step is 40 % saturation (1.75 M). Streptavidin remains soluble, the pellet can be discarded. After centrifugation the ammonium sulfate saturation is increased up to 70 % (3.37 M), Streptavidin is no longer soluble and precipitates.

The pellet is resuspended in a 50 % saturated ammonium sulfate solution (2.25 M), streptavidin again precipitates. After centrifugation the pellet is resuspended in 1x PBS buffer.

As a result the solution contains only those proteins, which precipitate between 40 % and 50 % ammonium sulfate saturation. One last centrifugation at 15000 rpm for 30 minutes removes insoluble impurities.

The solution is dialysed against 20 mM Tris/HCl buffer without salt (pH 8). Streptavidin has an isoelectric point of 6.09, therefore it is negatively charged in its buffer and a positively charged ResQ column is used for ion exchange chromatography. An increasing salt concentration of the buffer causes fractional elution of protein.

Streptavidin monomers, tetramers and aggregates can be identified by gel filtration with a sephacryl column.

After sterile filtration, a UV/VIS spectrum of the solution is measured in order to determine its concentration.[8]

The production of Traptavidin, Strep-Tactin and enhanced monomeric Avidin is analogue.

Figure 2: Production and purification of streptavidin

Biotinylated PAS-Lysine for cross linking

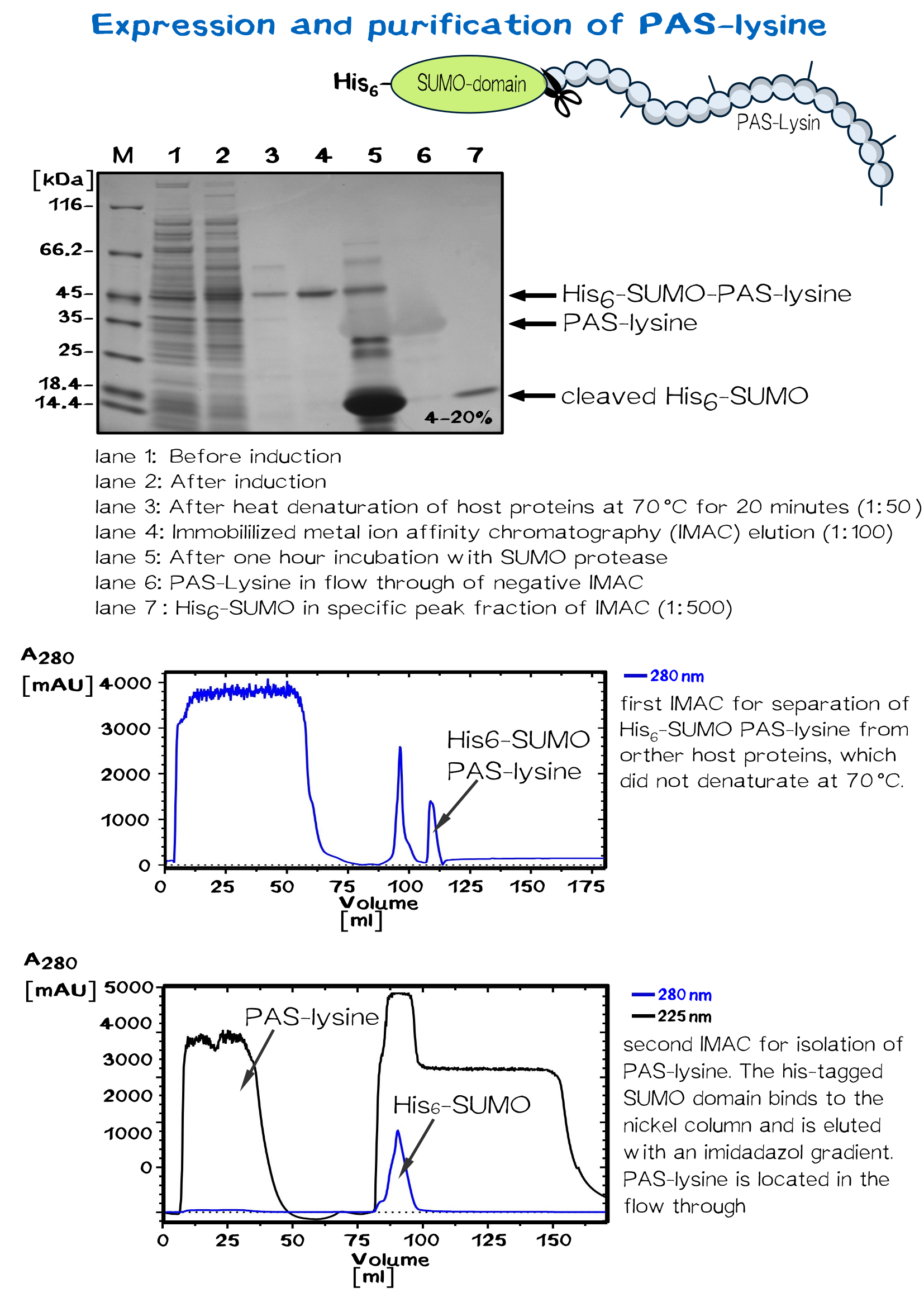

Biotinylated SUMO-PAS-Lysine is used as a linker molecule in the biotink technology. The PAS-Lysine linker is fused to SUMO protein domain, which carries a N-terminal His-tag and therefore provides simple purification.

The PAS-Lysine sequence is 201 residues long and consists primarily of the three amino acids Proline, Alanine and Serine. This hydrophilic and uncharged polymer is very good soluble. Ten lysine residues occur in the sequence and allow chemically biotinylation at the terminal amino group of each lysine residue.

Plasmid genetic

Production and purification

A 50 ml preculture with E.coli BL 21/R carrying the pSUMO plasmid is poured into a shaking flask with 2 L LB medium. After the bacterial suspension reaches an optical density of 0.5 the production of PAS-Lysine is induced by adding IPTG (1 mM).

The cells are harvested (5000 rpm, 30 minutes) after five hours and resuspended in 20 mM Tris/HCl buffer with 500 mM salt, pH 8. The cells are homogenized by French press or PANDA and centrifuged at 11500 rpm for 30 minutes. SUMO PAS-Lysine is very good soluble and therefore occurs in the supernatant, the pellet is discarded.

SUMO PAS-Lysine has the property to remain native even at high temperatures, where most protein denaturate. Heating the solution up to 70 °C for 20 minutes and centrifugation afterwards removes nearly all other proteins.

The solution is dialysed against IMAC buffer (50 mM sodium dihydrogen phosphate and 500 mM salt, ph 8) and injected on a chromatography column packed with nickel. After washing away impurities, the addition of imidazole results in elution of the SUMO PAS-Lysine.

The SUMO domain has no further use and is cleaved off by the SUMO-protease ULP ( ). Another IMAC chromatography separates the PAS-Lysine from SUMO domain, which binds specifically to the column. PAS Lysine can be identified in the flow through via UV absorption. Because PAS-Lysine does not contain aromatic residues, its absorption at 280 nm is very low, while the absorption at 225 nm (amid bondage) is remarkably high.

The proper fractions are pooled and the solution is dialysed against a physiologically buffer like 20 mM Tris/HCl with 500 mM salt, pH 8. The linker molecule can now be biotinylated.

- ↑ http://www.expasy.org/

- ↑ Weber, P. C., Ohlendorf, D. H., Wendoloski, J. J., & Salemme, F. R. (1989). Structural origins of high-affinity biotin binding to streptavidin. Science, 243(4887), 85.

- ↑ Weber, P. C., Ohlendorf, D. H., Wendoloski, J. J., & Salemme, F. R. (1989). Structural origins of high-affinity biotin binding to streptavidin. Science, 243(4887), 85.

- ↑ Stayton, P. S., Freitag, S., Klumb, L. A., Chilkoti, A., Chu, V., Penzotti, J. E., ... & Stenkamp, R. E. (1999). Streptavidin–biotin binding energetics. Biomolecular engineering, 16(1), 39-44.

- ↑ Weber, P. C., Ohlendorf, D. H., Wendoloski, J. J., & Salemme, F. R. (1989). Structural origins of high-affinity biotin binding to streptavidin. Science, 243(4887), 85.

- ↑ Schmidt, T. G., & Skerra, A. (2007). The Strep-tag system for one-step purification and high-affinity detection or capturing of proteins. Nature protocols, 2(6), 1528-1535.

- ↑ Lee, J. M., Kim, J. A., Yen, T. C., Lee, I. H., Ahn, B., Lee, Y., ... & Jung, Y. (2016). A Rhizavidin Monomer with Nearly Multimeric Avidin‐Like Binding Stability Against Biotin Conjugates. Angewandte Chemie International Edition, 55(10), 3393-3397.

- ↑ Skerra, A., Gebauer, M., Schönfeld, D., Schmelz, E. (2007). Skript zu "Fortgeschrittenenpraktikum Proteinchemie"