(→The sub-projects of biotINK and their achievements) |

(→The sub-projects of biotINK and their achievements) |

||

| Line 30: | Line 30: | ||

== [https://2016.igem.org/Team:LMU-TUM_Munich/Proof Proof of principle for the avidin-biotin "polymerization"] == | == [https://2016.igem.org/Team:LMU-TUM_Munich/Proof Proof of principle for the avidin-biotin "polymerization"] == | ||

[[File:Muc16_Sticker_Proof_001.png |right|200px]] | [[File:Muc16_Sticker_Proof_001.png |right|200px]] | ||

| − | + | We chose the avidin-biotin system because of their high affinity and rapid association. Our successful polymerization tests showed that cell density, concentration of biotinylated BSA in the bioink, and streptavidin concentration in the reservoir are the three major factors that impact performance. Thus, more BSA entailed higher structural integrity. We successfully printed defined objects with our technology and developed an optimal ratio of constituents. Aggregation was visually confirmed in the micromanipulator. | |

<br><br><br><br><br> | <br><br><br><br><br> | ||

== [https://2016.igem.org/Team:LMU-TUM_Munich/Demonstrate First bioprinting results using the biotINK bioprinter] == | == [https://2016.igem.org/Team:LMU-TUM_Munich/Demonstrate First bioprinting results using the biotINK bioprinter] == | ||

[[File:Muc16_Sticker_Demonstrate_001.png |right|200px]] | [[File:Muc16_Sticker_Demonstrate_001.png |right|200px]] | ||

| + | We successfully produced first prints of defined spatial structure in our bioprinter and show that our technology compares favorably with existing Inkjet and microextrusion technologies in bioprinting, especially in terms of cell viability. | ||

<br><br><br><br><br> | <br><br><br><br><br> | ||

== [https://2016.igem.org/Team:LMU-TUM_Munich/Hypoxia A vascularization inducer based on a hypoxia-sensitive promoter] == | == [https://2016.igem.org/Team:LMU-TUM_Munich/Hypoxia A vascularization inducer based on a hypoxia-sensitive promoter] == | ||

[[File:Muc16_Sticker_Hypoxia_001.png |right|200px|]] | [[File:Muc16_Sticker_Hypoxia_001.png |right|200px|]] | ||

| + | |||

<br><br><br><br><br> | <br><br><br><br><br> | ||

== [https://2016.igem.org/Team:LMU-TUM_Munich/Safety Safety evaluation of our project and the kill-switch] == | == [https://2016.igem.org/Team:LMU-TUM_Munich/Safety Safety evaluation of our project and the kill-switch] == | ||

[[File:Muc16_Sticker_Safety_001.png |right|200px|]] | [[File:Muc16_Sticker_Safety_001.png |right|200px|]] | ||

| + | |||

<br><br><br><br><br> | <br><br><br><br><br> | ||

Revision as of 03:24, 20 October 2016

The sub-projects of biotINK and their achievements

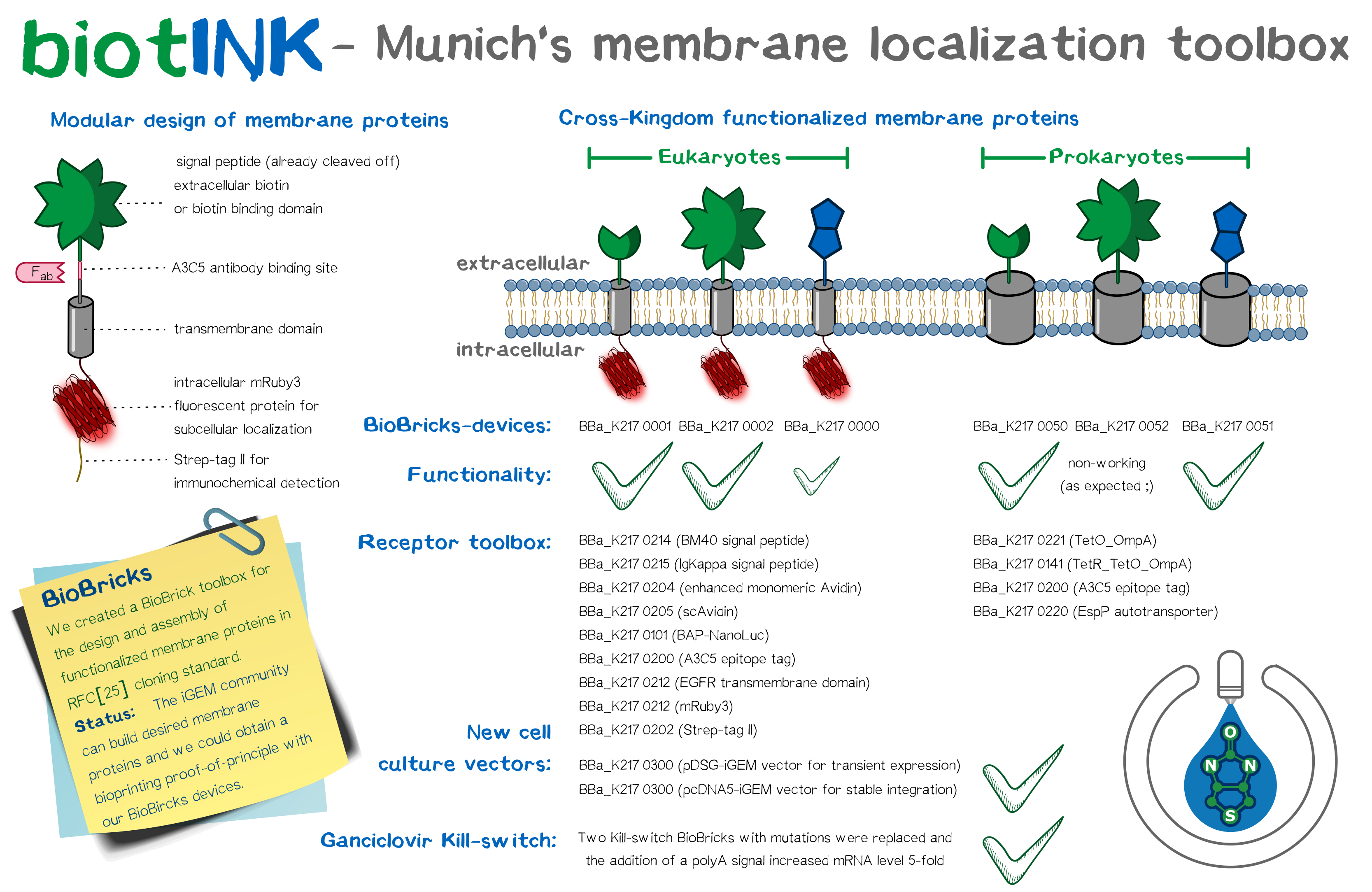

BioBrick Part Design

As does every sophisticated SynBio project, we designed a plethora of BioBrick constructs and devices in the course of our project. Most prominent among these are the modular transmembrane proteins we conceptualized, since they are integral to the functionality of our bioprinting system. Basing our workflow on the standard RFC[10] and RFC[25] assembly standards, we assembled the same intracellular and transmembrane domains, namely mRuby3 and the EGFR transmembrane domain, with different extracellular domains, among them single-chain avidin, monomeric avidin, and NanoLuc fused with an N-terminal Avi-tag for in vivo biotinylation by the co-expressed biotin ligase BirA. We coupled these constructs with a trafficking signal for membrane integration. Including further elements to stabilize these receptors offers advantages over previously assembled BioBricks, and planning our constructs with multiple options for detection provided us ample opportunity to extensively characterize the outcome. Apart from these eukaryotic designs, we drafted an autotransporter construct for bacterial surface display.

Production, purification & conjugation of recombinant proteins

As the second constituent of our two-component polymerization system next to the membrane proteins, we required large amounts of protein, either biotin-binding or bearing chemically introduced biotin depending on the receptor in question. For biotin-binding proteins, we produced and purified the avidin variants wt streptavidin; traptavidin,a variant with higher affinity toward biotin and enhanced thermal stability; streptactin, a variant that binds an oligopeptide sequence termed strep-tag; and enhanced monomeric avidin, which does not assemble into tetramers and is thus monovalent. wt Streptavidin was produced both in the dimensions of shaker flasks and a fermenter, and purified according to an established protocol. As a scaffold for chemical biotinylation, we produced and purified PAS-lysine and GFP. We extensively characterized all proteins as well as the biotinylated forms of the latter group plus BSA by ESI-TOF, SDS-PAGE, and IEF; moreover, we determined the affinity of streptavidin variants via fluorescence titration and their thermal stability using CD spectra. We produced all target proteins in good purity and successfully biotinylated PAS-lysine, GFP, and BSA.

A fully functional cross-kingdom membrane localization toolbox

Based on our modular membrane protein design, we evaluated the functionality of different signal peptide in shuttling the protein into the membrane. Apart from taking the BioBrick EGFR signal peptide, we designed two further signal peptides with increased translational efficiency, incorporating items such as the Kozak sequence. These three signal peptides were analyzed in silico as well as experimentally using a luciferase secretion assay. The BM40 signal, one of our self-designed constructs, was most efficient and thus incorporated into our other devices. Additionally, we incorporated three reporter modules (mRuby3, A3C5 epitope tag and strep-tag II) into the receptors. The finished constructs were used to generate semi-stablly transfected and stable cell lines. Protein localization was confirmed via fluorescence and high-resolution fluorescence microscopy, including characterization of a trafficking signal for increased membrane localization, and the recombinant protein was quantified by FACS and Western blot. mRNA expression levels were detected by RT-q-PCR. For visualization, aggregation of functionalized cells with Strep beads was subjected to SEM. The bacterial autotransporter was characterized and found to successfully shuttle small protein domains to the extracellular surface.

Chemical synthesis of amino-reactive biotinylation compounds

Apart from the standard biotin-NHS, several other derivatives spacing biotin and NHS apart by an amino acid residue were synthesized. These derivatives were used in the chemical biotinylation of BSA in order to assess their relative stability toward cleavage by the plasma protein biotinidase. The assay principle is based on a colorimetric reaction and was developed by ourselves. Compared to biotinylation via regular biotin-NHS, the derivative incorporating a spacer aminocaproic acid is cleaved somewhat faster, allowing to dissolve a cell mesh more quickly, and the spacer valine resulted in a drastically slowed hydrolysis rate.

Proof of principle for the avidin-biotin "polymerization"

We chose the avidin-biotin system because of their high affinity and rapid association. Our successful polymerization tests showed that cell density, concentration of biotinylated BSA in the bioink, and streptavidin concentration in the reservoir are the three major factors that impact performance. Thus, more BSA entailed higher structural integrity. We successfully printed defined objects with our technology and developed an optimal ratio of constituents. Aggregation was visually confirmed in the micromanipulator.

First bioprinting results using the biotINK bioprinter

We successfully produced first prints of defined spatial structure in our bioprinter and show that our technology compares favorably with existing Inkjet and microextrusion technologies in bioprinting, especially in terms of cell viability.

A vascularization inducer based on a hypoxia-sensitive promoter

Safety evaluation of our project and the kill-switch

InterLab study: Determining reliability of measurements

Entrepreneurship

Hardware

Software

Measurement

Model